-

Component Process

-

CHRA/Cartridge Assembly

-

Complete Turbo Assembly

-

Logistic Service

-

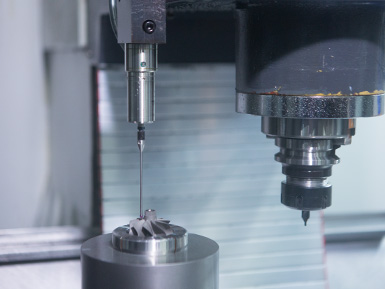

> OKUMA

> Shaft CNC

-

.jpg)

> OKUMA

> Shaft Grinder

-

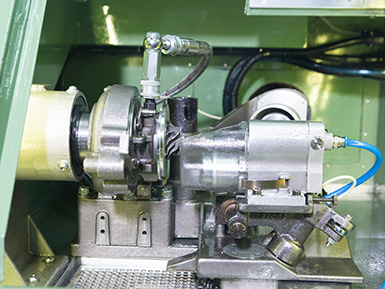

> SCHENCK

> Automatic Shaft Balancing

-

> MAZAK

> Hole Punder

-

> MAZAK

> Wheel CNC

-

> SCHENCK

> Automatic Balancing Wheel

-

> TSUGAMI

> Wheel Grinder

-

> TSUGAMI

> Bearing Housing Welding

-

.png)

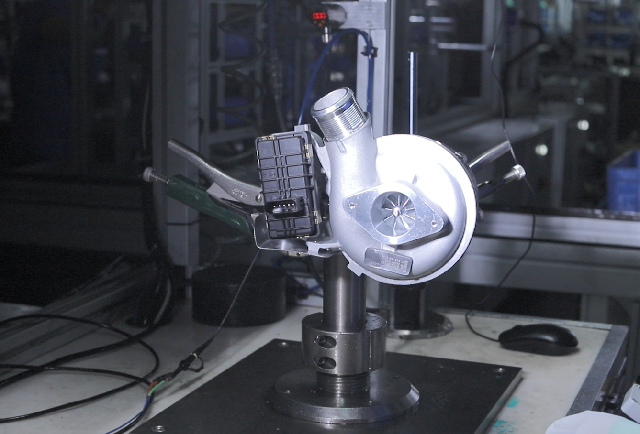

> VICI

> Optical Measurement Instrument

1. Broad model coverage

2. Quick model update

3. Dedicated discharge equipment for the easy deformation parts, which would avoid knocking parts together, or twisting each other

4. Material Picking System for the short packing parts, which would guide the operator to pick up the material and put the wrong alarm

5. Computer controlled production process to prompt assembly steps in real time, which records production information as well as process parameters

6. 100% automatic detection for the airtightness of each and every cartridge

-

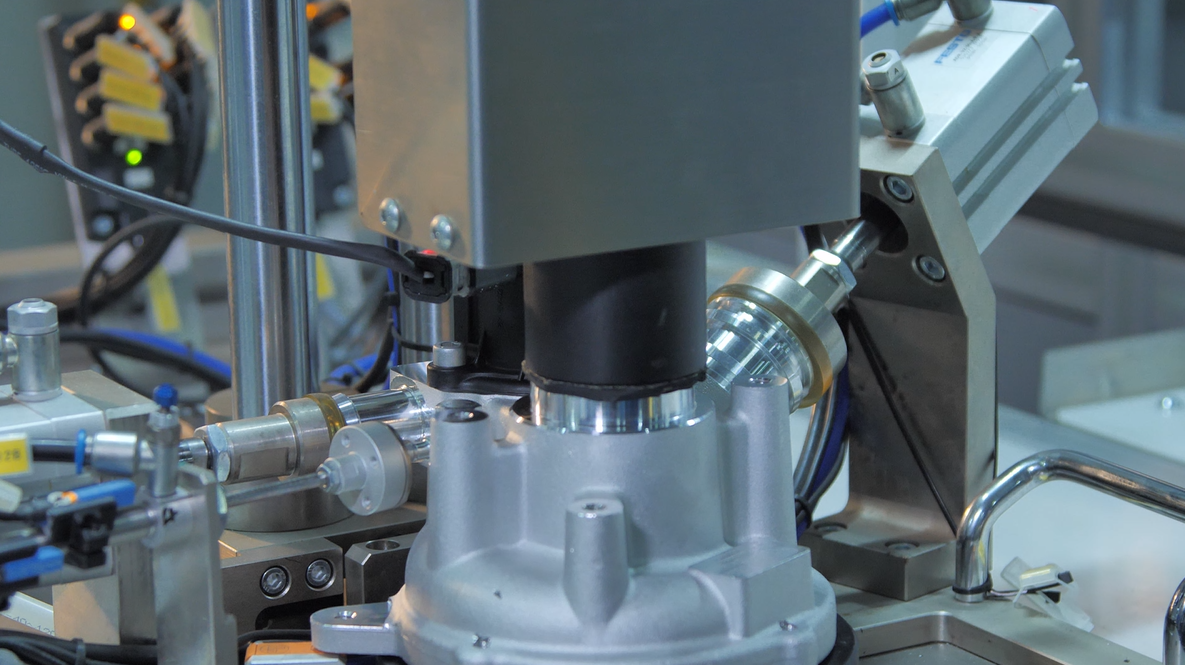

> Assemble and Detection

-

> Calling Program

-

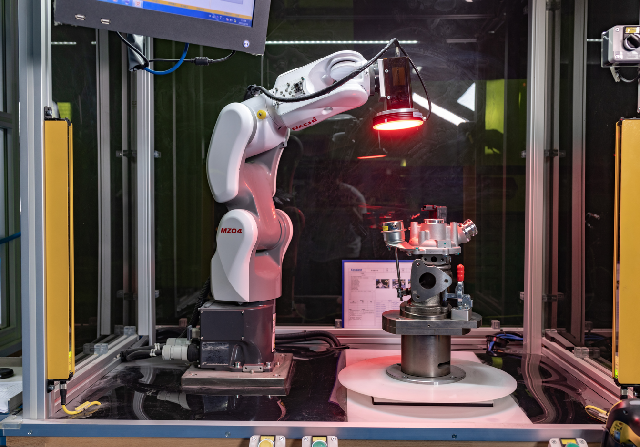

> VSR (vibration sorting rig) core component balancing

-

> VSR Core Component mapping

-

> Modification to Core Components

-

.jpg)

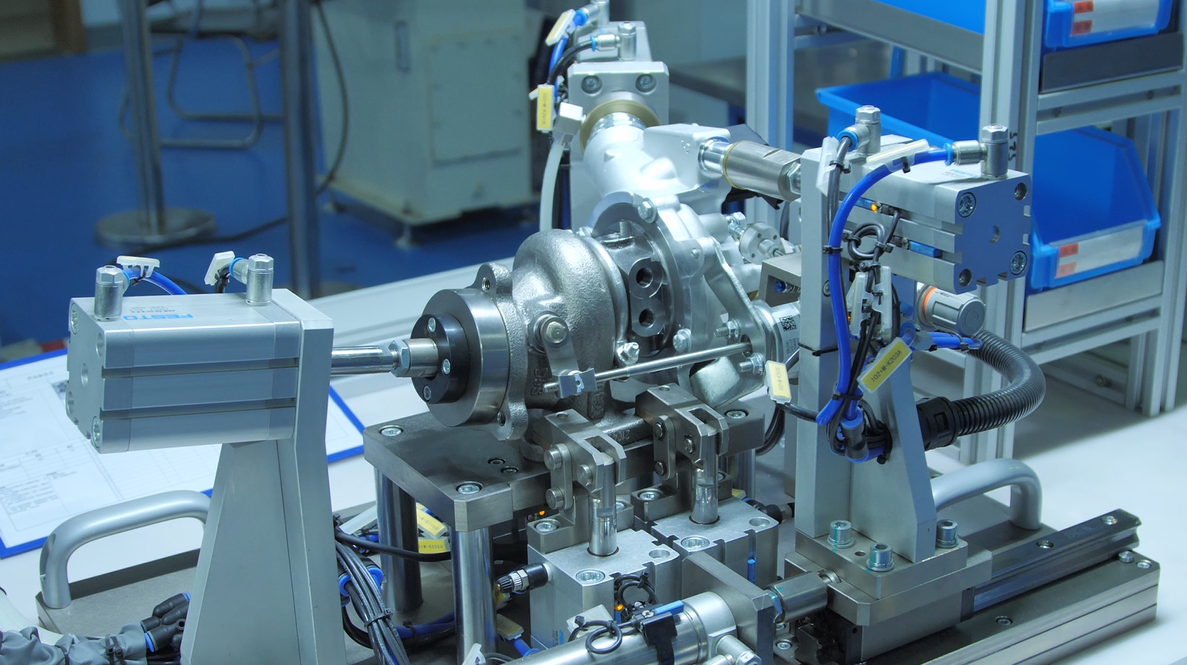

> Assemble and Detection procedure

-

> Core Component Assembly

-

.jpg)

> Comprehensive Testing of Core Components

-

> High-speed Dynamic Balancing of Core Components

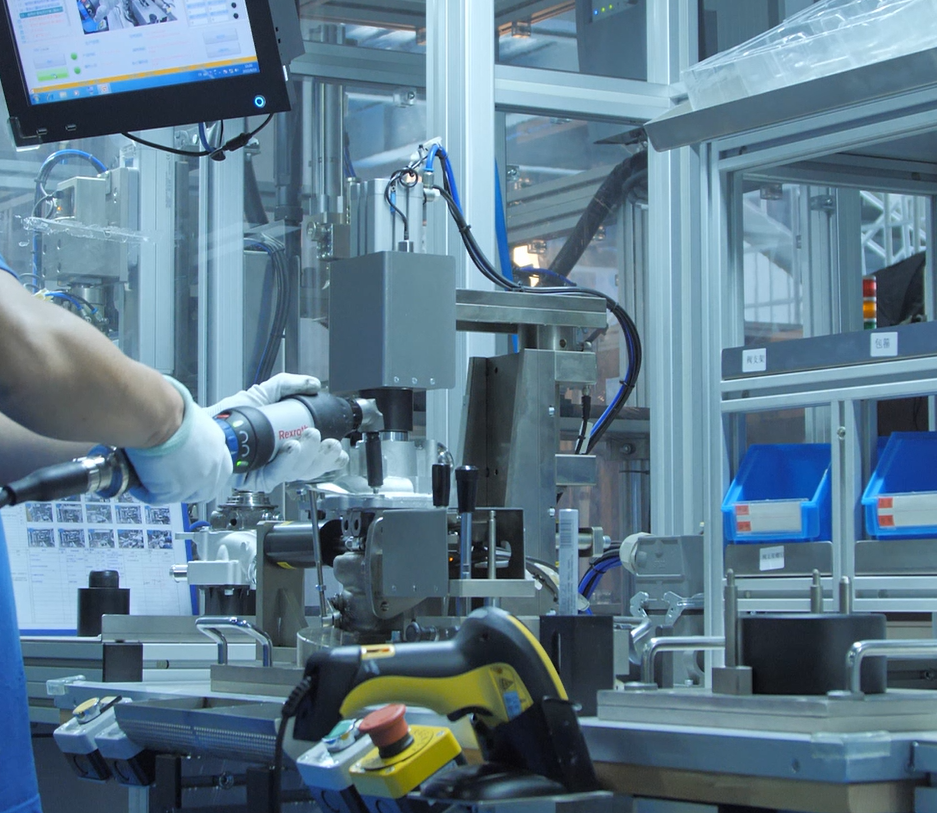

1. Broad range coverage

2. Quick model update

3. The operating procedure for each model is independent. Electronic operating files run in concert with product assembly tools. The illustrations that are presented to the operator offer the most intuitive operating instructions

4. Lean Management Systems govern the factory's entire equipment layout, with the whole process using a conveyor system to efficiently revolve materials

5. Material Picking System is ultilized for the short packing of parts, which guides the operator to pick up the correct part and raises an alarm if an incorrect item is selected

6. The Casting assembly uses a program-controlled servo system to ensure product consistency

7. Again, the entire production process is computer controlled so as to prompt the assembly steps in real time, and also record production information and process parameters

8. 100% automatic detection for the airtightness of each Turbocharger assembly

-

> Housing Assembly and Inspection

-

> Housing Assembly and Inspection

-

> Actuator Calibration

-

> Variable Cross-section Flow Testing

-

> Air Tightness Testing

-

> Visual Inspection

-

(2).jpg)

> 4500ŃÄĪ Warehouse Ensue Adequate Inventory

> 5500 Positions for Turbo, Core and Housings

-

.png)

> ERP & WMS Systems

> QR code implementation

-

> 7 days for standard order turnaround

> 2 days for urgent orders

Login

Login