1. Failure Analysis

Compressor housing Oil Leakage:

Loose, deformed, or ruptured intake pipes of the Turbocharger can lead to Compressor housing oil leakage; a dirty air filter can cause dirt accumulation on the Turbocharger impeller, resulting in Compressor housing oil leakage; damage or bending of the Turbocharger return pipe can cause poor oil return, leading to Compressor housing oil leakage; impeller damage from foreign objects or excessive axial and radial clearances can also result in Compressor housing oil leakage.

Turbine housing Oil Leakage:

Excessive axial and radial clearances at the Turbine housing can cause oil leakage in the Turbocharger; damage or bending of the Turbocharger return pipe can lead to poor oil return, causing oil leakage at the Turbine housing; overfilled crankcase oil can hinder oil return, resulting in Turbine housing oil leakage; dirt or coking accumulation in the bearing housings, blockage at the oil return port can also cause oil leakage at the Turbine housing; a blocked engine crankcase breather can also lead to Turbine housing oil leakage.

2. Oil Leakage Cases

Compressor housing Oil Leakage Case

Turbine housing Oil Leakage Case

.png)

3. Design Improvement Cases:

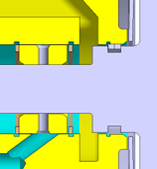

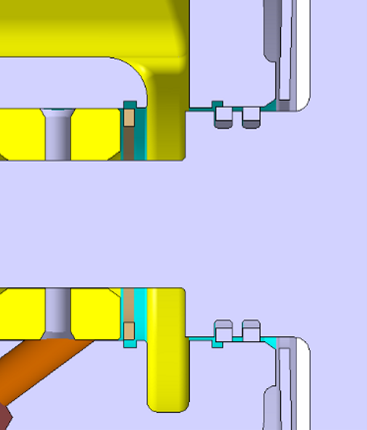

Redesigning the Compressor housing side or Turbine housing side of the Turbocharger to enhance sealing effectiveness, effectively preventing oil leakage due to poor sealing.

.png)

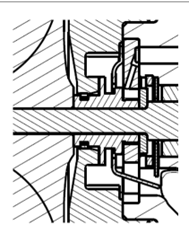

Before Redesign: (Single Ring) After Redesign(Double Ring)

Turbine housing Redesign Case

Before Redesign - Single Groove Double Ring After Redesign - Double Groove Double Ring

4. Process Control - Core Air Tightness Testing

During assembly, the Turbocharger undergoes 100% online core air tightness testing to prevent oil leakage due to misplacement or omission.

5. Oil Leakage Testing

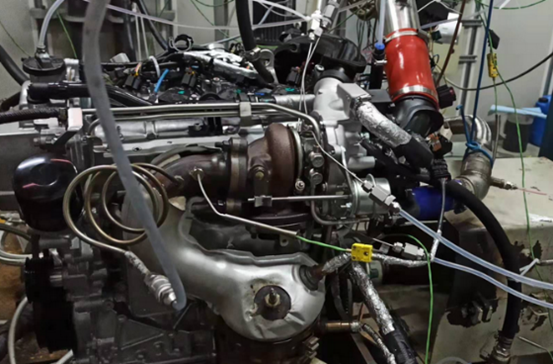

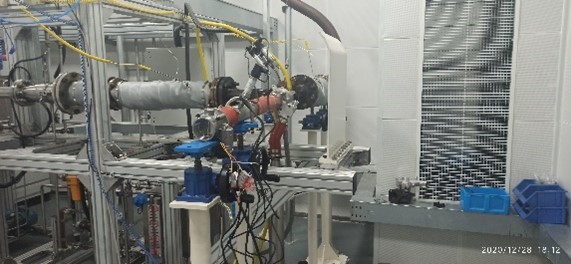

A- Turbocharger Bench Testing

Conduct bench testing on the Turbocharger to perform oil leakage tests, verifying the Turbocharger's ability to resist oil leakage under special conditions and confirming if the engine operating environment meets the Turbocharger's design requirements.

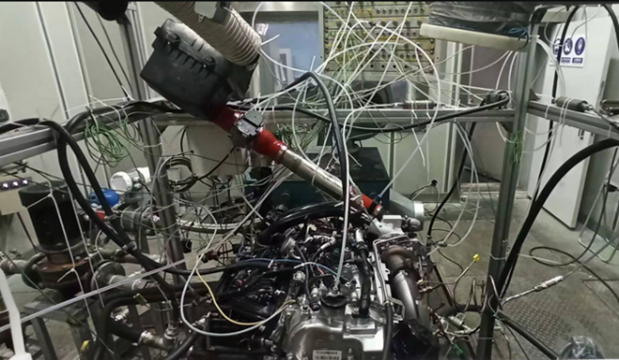

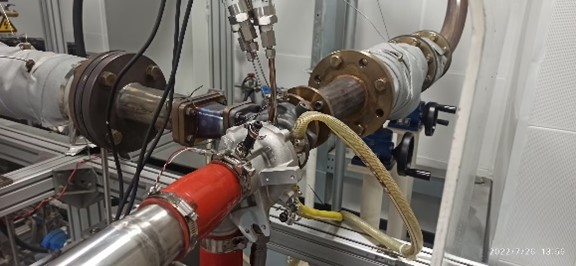

B- Engine Bench Testing

Conduct engine testing on the Turbocharger to simulate vehicle operating conditions, perform oil leakage tests, verify the Turbocharger's ability to resist oil leakage under special conditions, and confirm if the engine operating environment meets the Turbocharger's design requirements.